How wings are attached to the planes and how the wings support the weight of the engines and fuselage without snapping off?

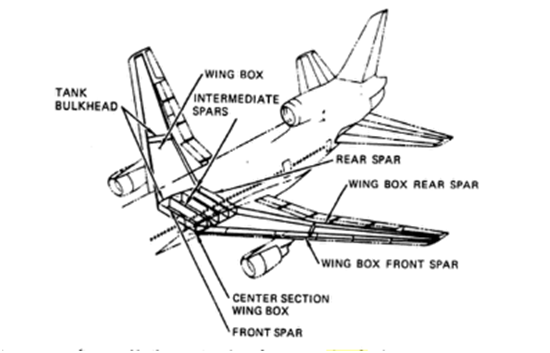

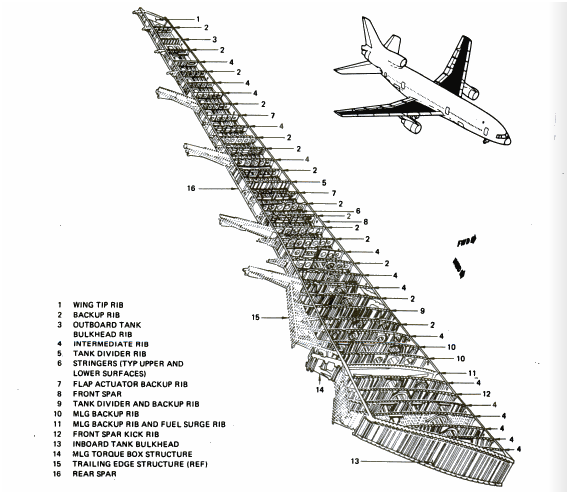

The main frame of a modern transport wing consists of spars, ribs, bulkheads, and skin panels. The structural strength of the wing could carry its own weight, the weight of the fuel, the weight of the engine and the forces imposed by aerodynamic forces and landing gears. Wings are constructed in three assemblies such as left, right and center wing sections and are joined as single piece wing.

The wings consist of spar which helps to carry load on the wings and provide supporting structure for fittings attaching engine pylons, main landing gear and flight surfaces to the wing.

The main wing is attached to the center fuselage with wing box.

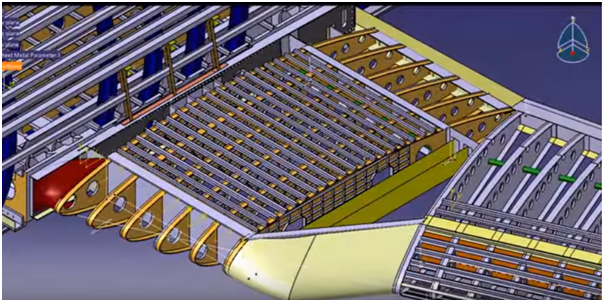

Center wing Box Structure of the airplane

Multiple spars used in Lockheed Martin Aircraft

Internal Structure of Transport Aircraft Wing

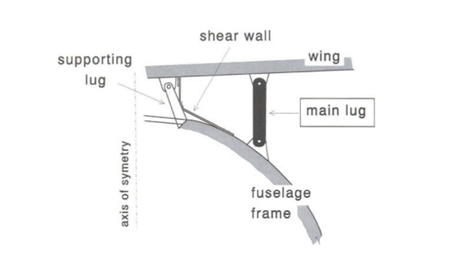

Wing Attachment To The Fuselage

Location of Main lug in wing-fuselage attachment

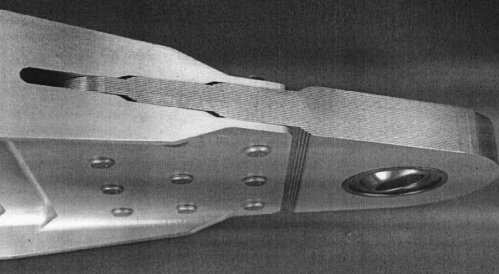

The wings are attached to the main fuselage body using a lug. The lug attachment helps to attach the wing with the fuselage.

The bending moment and shear loads from wing to the fuselage structure is transferred through the lug structure. The attachment is done by series of pinned lug between wing side of wing box and fuselage.

Lug of an CN-235 aircraft Wing-Fuselage attachment

The connection between the wing and the fuselage of the aircraft occurs with four lugs, two at the front spars and two at the rear spar.

How The Wings Hold The Engines?

Wings are the primary lifting surface of the aircraft. The material used to make wings in modern aircraft are aerospace grade aluminium.

Many recently developed aircrafts like Boeing 787,777X, Airbus A350 XWB uses light weight composite materials like carbon fibre and glass fibre. This will increase fuel efficiency

The aluminium used in coke cans are 8000 times less stiff than aerospace grade aluminium. The aerospace grade is produced by using aluminium alloy.

The wings are the easiest place to hold the weight of the engine and the fuel. The aerodynamic forces help to lift the wings due to their airfoil shape and so it also helps to lift the weight of the wing along with the weight of engine and fuel.

The Fear Of Snapping Off

The wings consist of spars inside the wing structure.

There are two or more main spars and intermediate spars between main spars. The intermediate spars support carrying operational loads. The main spars assist in carrying loads from engine payloads, fuselage, landing gear and flight surfaces.

The wings cannot be snapped off from the wing due to their structure which was built using the spars and ribs.

Wings Tests To Allay Fear Of Snapping Off

Wing test of Airbus A350 XWB at Wing Test Facility

The wing tests are done by every aerospace giant to prove the wing’s strength and test its threshold limit to carry loads on it.

Wing of Boeing and Airbus aircraft usually handle 154% of its design load before breaking from the fuselage.